I bought the Record Power DML305 lathe recently and would like to share here some facts with you. All in all I like the machine very much and can clearly recommend it. I have never had a lathe before, so I'm not able to give you a very objective opinion. I didn't discover any bad surprises in functionality or built quality.

The lathe is very silent and makes less noise (idle) than any other woodworking tools I have. With nearly 40 kg it's a sturdy piece of tool.

The M33 mount version has a "native" thread and no adapter on a smaller thread. The Morse taper is #2 as in the tailstock. MT2 is a very common size with a bigger variety of tools than MT1.

The centers are perfectly aligned in both horizontal and vertical direction (at least for woodturning scales). The lathe doesn't vibrate when running idle.

The main lock works in both directions. This avoids collisions with the lock for the tool rest height. All the other handles are angle-adjustable and you can turn them away from you for comfortable and safe operation.

The heavy cast iron bed is finished where necessary. The tailstock moves smoothly over the bed.

Dimensions

The size of the machine was an important factor for me sine my hobby "chamber" is quite small. The DML305 is very compact with storage dimensions of about 82 x 40 x 25 cm (W x H x D). In operation some more lateral space is needed. The belt change door needs roughly 30 cm when fully open.

The tailstock extends about 18 cm over the bed at full capacity. It can be removed quickly when working on boxes or bowls.

You will need at least 100 cm of space to operate the lathe.

The indexing lock can arrest the spindle at 12 positions. I use it only for fixing and releasing the chuck. The lock can be removed for storage.

With a depth of about 25 cm the lathe can be stored in a shelf when not in use. Removing the tool caddy attached to the back will give 1-2 cm less depth.

Capacity

The maximum distance between the driving center and the revolving center shipped with the DML305 is 405 mm. The 393 mm in the official documentation is a conservative specification (=15 inch). The maximum diameter of the workpiece is 305 mm. Please note, the axial dimensions will be reduced after installing a chuck by 5-6 cm. A drill chuck in the tailstock will need another 6-12 cm.

The tool rest dimensions match the lathe dimensions well and are enough for the biggest diameter. I never turned such big pieces on the lathe so I can't tell you if the construction is sturdy enough for vibration free operation.

The supplied face plate has a diameter of 83 mm and four holes for mounting wood for bowls.

Motor and gears

The lathe has six manually changed gears. Changing gears takes about 30 s and is easier than expected. You just have to learn the trick: Unlock the tensioner, use one hand as a derailleur like in a bicycle gear shift, use the other one to rotate the belt. Big to small wheel change comes first. The slowest speed is 360 rpm. At this speed you can safely turn any unbalanced piece of wood, very convenient. The maximum speed is 3250 rpm. Quite frightening with a big chuck on the spindle.

The motor power of 375 W seems not very high, but I never experienced the need for more power, at least with wood diameters <15 cm. The good thing about belt gears is the constant power. When speed reduces, the torque rises. The motor becomes quite hot during operation. There is even a small label stating that.

Tailstock

The tailstock has a Morse taper #2 (MT2). Some web sites list an MT1. The M33 and the 3/4" version might have different taper sizes. Check the diameters before you order accessories. The tailstock spindle can be locked, but I never used this feature up to now. The travel distance of the tail spindle is about 62 mm. It has a marking in inch. Centimeters would be great...

The tailstock of the DML305 has a through-hole for knocking out the mounted tools or drilling long holes.

Knocking out tools is usually not necessary. They are pressed out by cranking the spindle back to the bottom position. I don't know if this trick is in the specs of the Morse taper or just a side effect. Anyway, it's practical.

Accessories

Record Powers offers several accessories in cooperation with other manufactures. I bought the Teknatool Supernova 2 chuck set which fits the machine well. It's a little bit heavy for a midi lathe but a pleasure to work with. The drill chuck from Record Power is very compact, but I went for a keyless version from Paulimot (DE). The keyless chucks are longer.

Not so great...

There are two things in the machine that are obviously a bad solution. The belt change door is locked with a simple Allan screw. Each time you need to change the gear you need to grab the hex key and loosen the screw on the left hand side. Unless you are a lefty, it's rather inconvenient and takes time. The user is tempted to run the wrong speed. I replaced the screw with a knob. This knob should become the fist turning exercise. A clamp would be the best solution.

I didn't like the power switch covered with a pseudo emergency button. Should this cover stop kids from playing with the machine? I don't know, but I removed the cover quite quickly. You can lever it out from the hinge easily. With the cover you have no quick access to the OFF button.

Both issues smell a little bit like safety regulations artefacts. Dear customer, it's a toilet brush, don't brush your teeth with it...

The last thing worth mentioning is the motor suspension. The engineer in you will tell you immediately that the motor should not hang on one side like in the picture below. In my DML305 I had to tighten one screw holding the motor assembly (inside the bed) and the problem was solved. Just observe the motor angle after setting up the lathe for the first time.

All cons described here are no real show stoppers and easy to improve.

Verdict

Every review needs a verdict;) The novice says: Yes, go for this lathe. It's compact, silent, heavy and well finished. No bad surprises, as often experienced with cheaper tools. You will not need a barn for it, which is an important factor for the amateur.

It's in the upper price range of the cheapos (2015). The question I can't answer is, if the cheaper machines offer the same value. Compared to it's competitors it has a slightly bigger swing and the slow 360 rpm gear. The latter seems more important to me. You can buy a bed extension if more axial capacity is needed, but there is no "swing extension".

There is also the Record Power DML305VS variable speed version for at least double the price of the fixed speed version. I hope the extra money goes into something else than just a couple of semiconductors. The different tailstock of the VS suggests that.

Just for clarification: Although "Record Power" sounds like "Glowing Dragon" or "Top Performance", the negative connotation with disposable drill sets from the supermarket is wrong;)

Happy turning,

Luk

PS: Let me know if you have questions. I will add the data to the article. I would be very happy if someone translates the metric dimensions into imperial units with all the fractions.

Hi Luk,

ReplyDeleteThinking of buying thus lathe, nearly a year in is it still living up to your expectations?

Cheers

Hi Chris,

Deleteyes, I still have the lathe and I'm very happy with it. No cons up to now. I like it's size (I have limited space) and I never reached the diameter or length limit. Up to now there are no signs of any wear of unhealthy noise. I use it with the Nova G3 chuck.

Recently I've built a disk sander extension for it:

www.doc-diy.net/various/sandbox/

Now the lathe become a 2-in-1 tool.

Regards, Luk

This comment has been removed by the author.

ReplyDeletehttp://www.doc-diy.net/various/sandbox

ReplyDeletethe clickable link...

That'll do me fine. Disc sander would be a great addition to my garage too. Thanks for replying.

ReplyDeleteHello Luk

ReplyDeleteI've just bought the same lathe and am setting it up now. The manual clearly says that to remove faceplate 'insert knockout bar into circular hole in the spindle nose' and says indexing mechanism should not be used as method of holding spindle to remove face plate, chuck or othervaccessories. My machine has no hole in the spindle! Am I missing something very obvious? If so a word to set me straight would be appreciated!!!

Thanks for the great post.

Peter

Hello Peter,

ReplyDeleteI just checked and there is no hole in the spindle. I usually use the indexing lock to block the spindle, exactly opposite to what the manual says. You can remove the indexing pin and stick the knockout bar in the hole. The indexing device is anyway of no great use since it has too much clearance and doesn't lock the spindle completely.

I guess, the statement about the spindle hole has been copied for a different model or I missed something obvious too.

Luk

Hello Luk

DeleteThanks for prompt reply. I think you must be right and my manual is for earlier model. I'll do as you do and your comments will mean I'll not be so worried doing it! Cheers

Peter

Hi, your review is very good and informative, however the cover for the on off button is the off button, you simply press it to switch off without having to open it first.

ReplyDeleteHi, your review is very good and informative, however the cover for the on off button is the off button, you simply press it to switch off without having to open it first.

ReplyDeletereally useful review, thank you. I might just take the plunge from hand to tool!

ReplyDeleteThe off button is actually an emergency stop. Really a health and safety issue. if you get something court in that chuck you maybe sorry for taking that big red button of.

ReplyDeleteRegards,

Ken

Hi DOC,

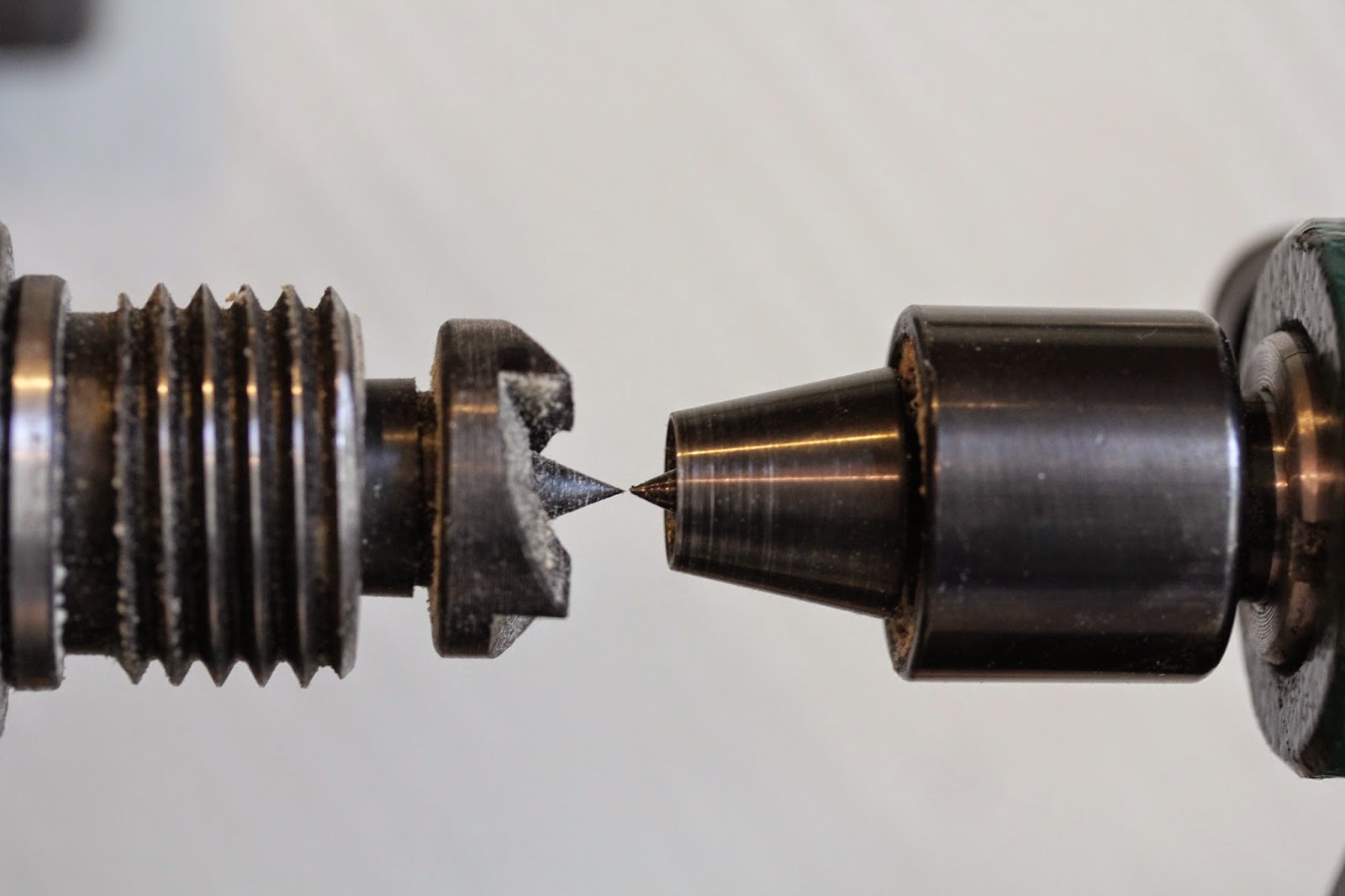

ReplyDeletecomment about your picture nr 2 ( from top ). That thread is a specific way to link a tool with MT2 , those tools have a thread on 20 mm length same 32 mm diam but with another step [ if yours is M32 step 1.5, on tool is M32 step 1 ] and both a secured with a special NUT that is half with a thread and half with the second one. NUT is driven via 32 key ,he has 4 side channels 8 mm tall with depth according with that key. Both are build according DIN 228-2 but i really can't find the right name for it. Was common in '85..'92 , i do use a CNC with a bunch of such tools. But I don't have a supplier :) Good luck!

Hello, I have a very similar lathe in the USA - a Delta midi. It's been satisfactory, and last year I made some improvements - I built a heavy bench with a sandbox to reduce vibration, and most importantly I changed out the motor for a variable speed 2HP DC motor that I scavenged from a treadmill. The pulley on the treadmill has the same vee groove configuration (with just more of them) and so I was able to buy a compatible belt from www.beltsforanything.com. Now the speed is continuously variable from ~50-3000 rpm, with no belt changes (hurray!).

ReplyDeleteThat's a great idea

DeleteJust bought a DML305 and it has come with a 520w (0.7hp) motor and the tailstock graduations in inches and mm - looks like they've made a few changes.

ReplyDeletehow many money

ReplyDeleteI want to share a testimony on how Le_Meridian funding service helped me with loan of 2,000,000.00 USD to finance my marijuana farm project , I'm very grateful and i promised to share this legit funding company to anyone looking for way to expand his or her business project.the company is funding company. Anyone seeking for finance support should contact them on lfdsloans@outlook.com Or lfdsloans@lemeridianfds.com Mr Benjamin is also on whatsapp 1-989-394-3740 to make things easy for any applicant.

ReplyDeleteДобрый день.

ReplyDeleteВ крыжке для установке ремня должен быть шар к и скоба для быстрого снятия.Повидимому эти детали закончились на заводе,Смотрите инструкцию 11,6

Можно сделать самодельную,установите магнит